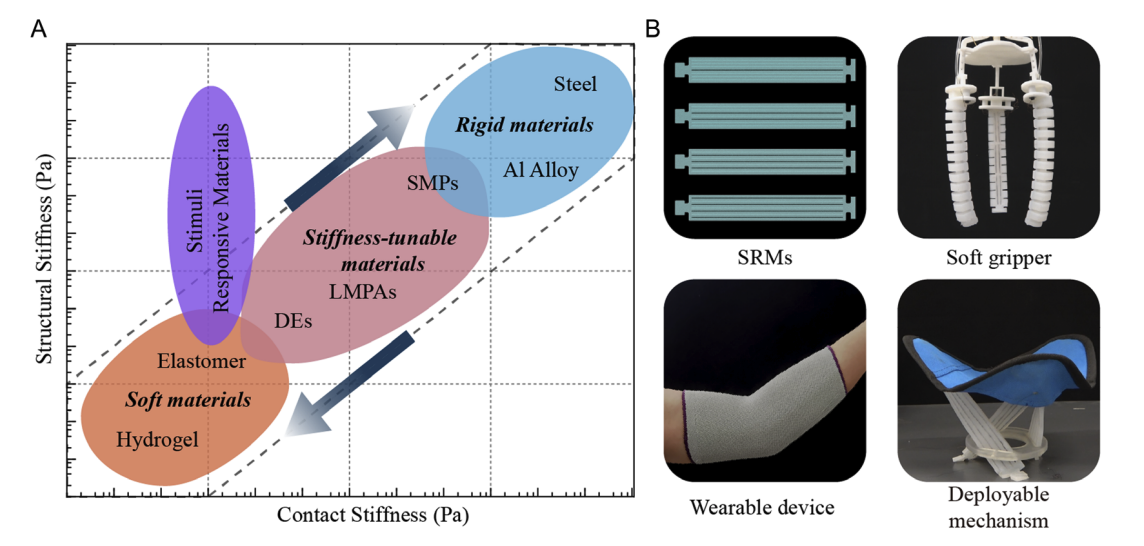

Stiffness regulation strategies endow soft machines with stronger functionality to cope with diverse application requirements, for example manipulating heavy items by improving structural stiffness. However, most programmable stiffness strategies usually struggle to preserve the inherent compliant interaction capabilities following an enhancement in structural stiffness. In this study, inspired by the musculocutaneous system, we propose a soft stimuli-responsive material (SRM) by combining shape memory alloy into compliant materials. By characterizing the mechanical performance, the flexural modulus increases from 6.6 to 142.4 MPa under the action of active stimuli, crossing two orders of magnitude, while Young's modulus stays at 2.2 MPa during programming structural stiffness. This comparative result indicates that our SRMs can keep a lower contact stiffness for compliant interaction although structural stiffness increases. Then, we develop three diverse soft machines to show the application potential of this smart material, such as robotic grippers, wearable devices, and deployable mechanisms. By applying our materials, these machines possess stronger load-bearing capabilities. Meanwhile, these demonstrations also illustrate the efficacy of this paradigm in regulating the structural stiffness of soft machines while maintaining their compliant interaction capabilities.

To enhance their versatility for diverse applications, soft machines often require stiffness-tuning strategies—for example, increasing structural stiffness to manipulate heavier objects. However, most existing programmable stiffness approaches struggle to maintain compliant interaction capabilities once structural rigidity is increased.

Addressing this challenge, researchers propose a stimuli-responsive flexible material inspired by the musculoskeletal system. The team demonstrates its application potential by developing three types of soft machines: a soft robotic gripper, a flexible wearable device, and a deployable structure for post-disaster rescue.

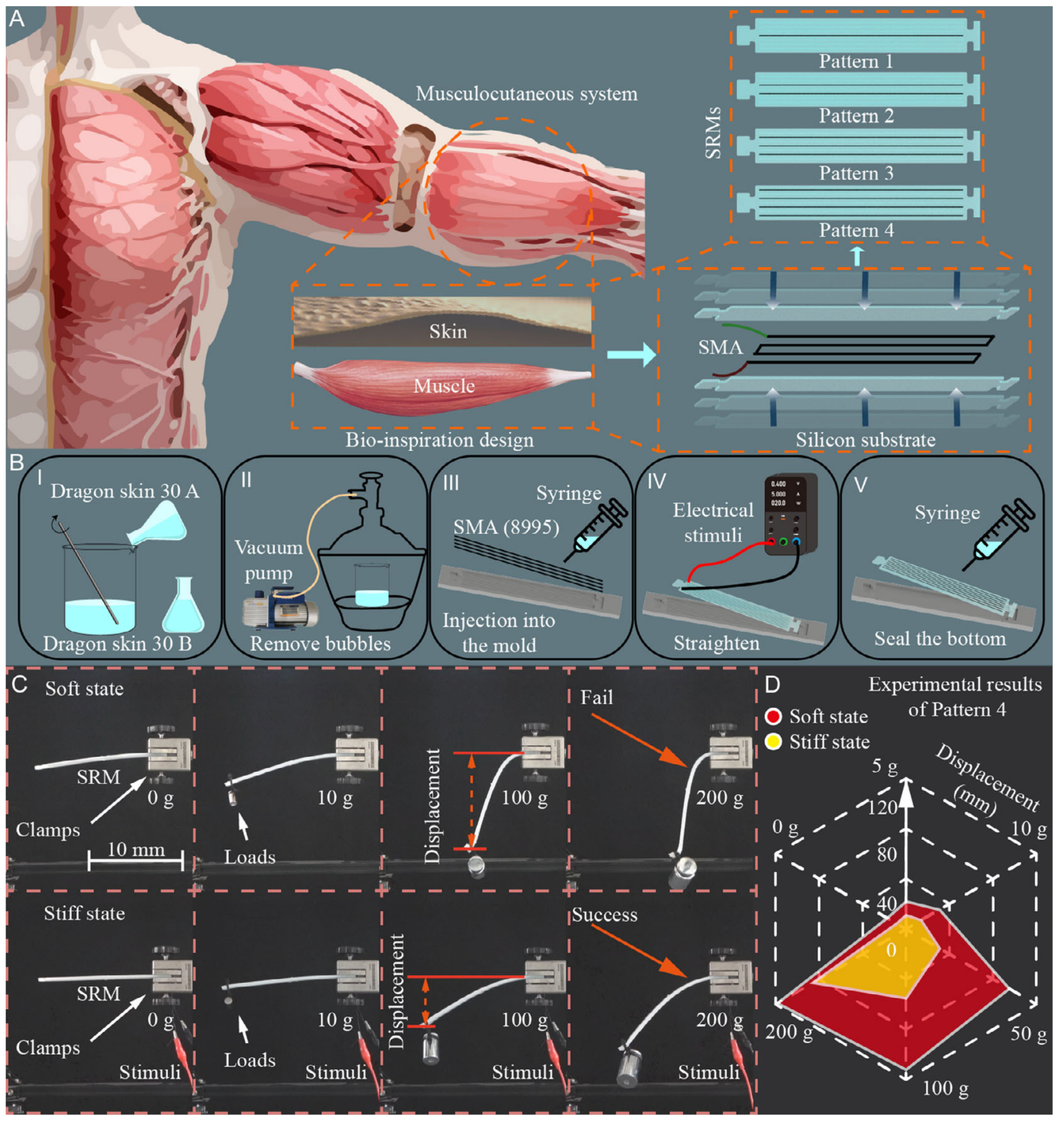

Biological systems reveal the complex interplay between structure and function, offering breakthrough ideas for the advancement of soft robotics. Muscle structures use chemical energy to produce various contraction responses and exhibit different stiffness levels between passive (minimal stiffness) and active (maximum stiffness) states, enabling stiffness modulation.

Meanwhile, the dermis—composed of collagen and elastic fibers—provides adaptive interaction capability. This biological paradigm inspired the development of an intelligent soft material (SRM) that integrates smart material components.

The SRM design incorporates two key components:

Unlike conventional SMA-driven soft robots, the SRM exhibits bio-like stiffness enhancement under Joule heating, enabling real-time mechanical modulation. At the same time, the silicone base maintains low contact stiffness, preserving compliance in environmental interactions.

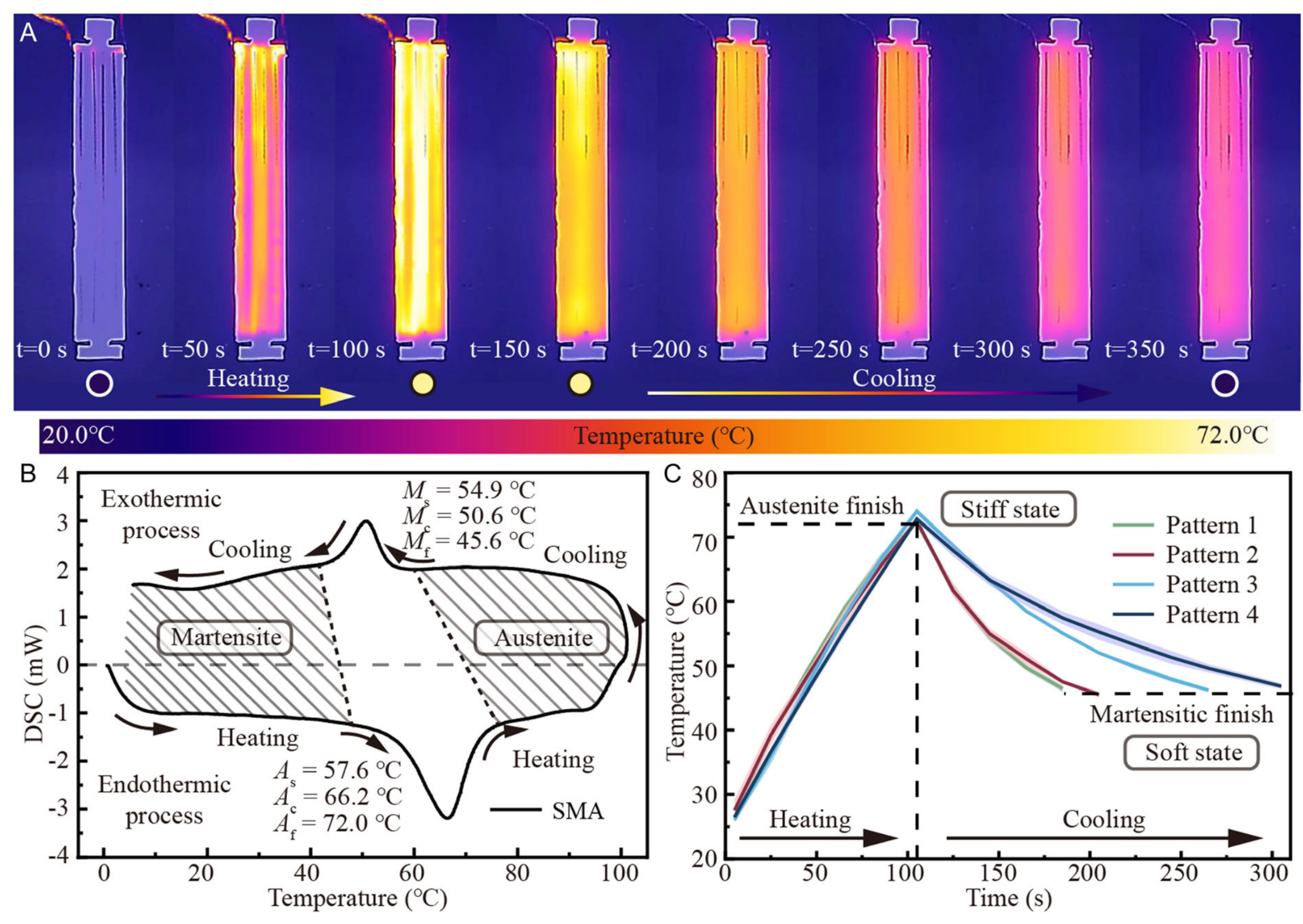

To characterize the thermomechanical properties of this material, the team recorded temperature changes using infrared thermal imaging during actuation and conducted DSC (Differential Scanning Calorimetry) experiments on the SMA.

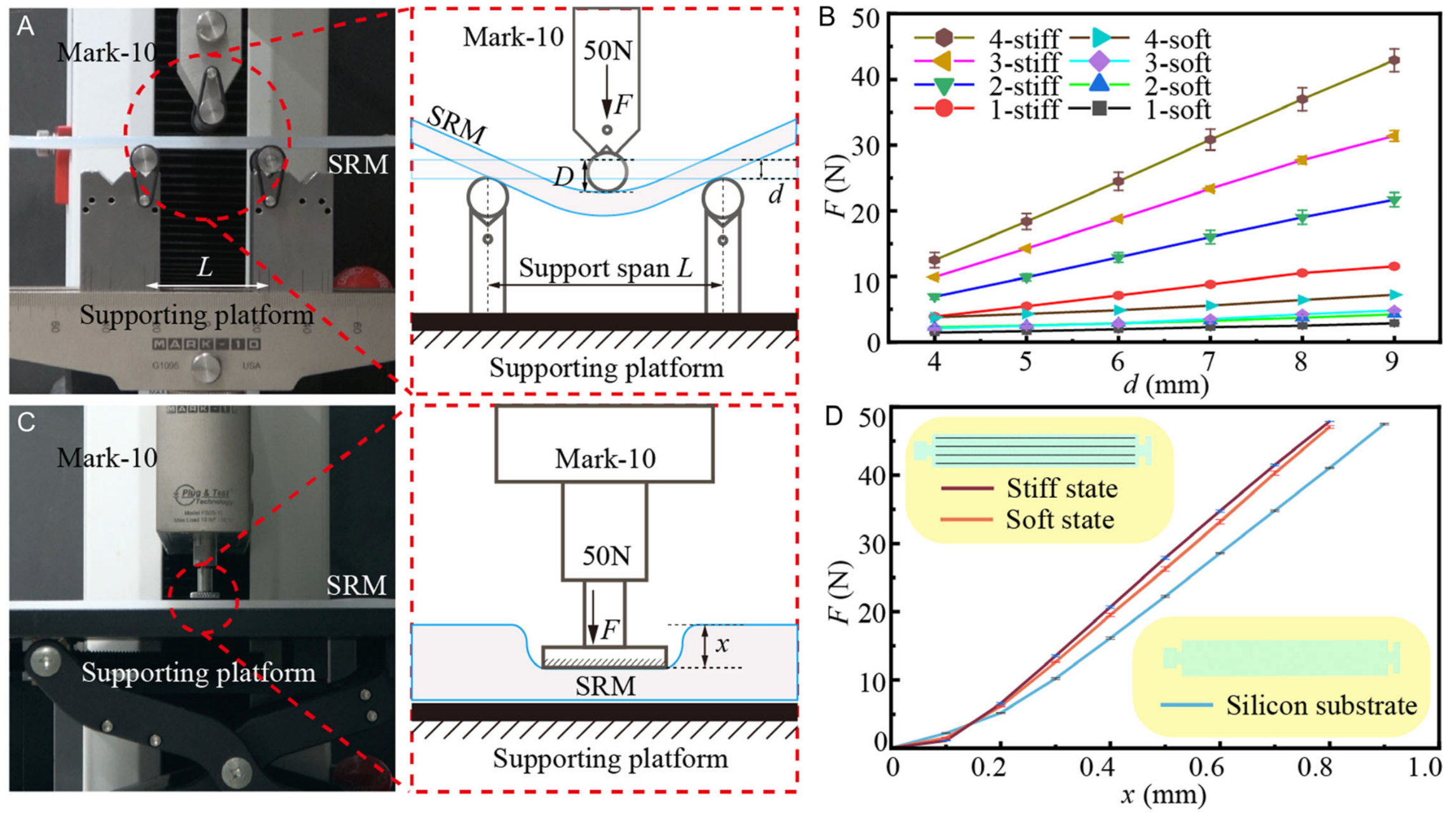

To validate both the stiffness modulation and compliant contact capability of the SRM, the team performed three-point bending tests and surface contact stiffness measurements. Results demonstrated remarkable performance:

The research demonstrates the application potential through three distinct soft machine implementations:

Enhanced grasping capabilities for objects of varying weights while maintaining gentle contact with delicate items.

Adaptive stiffness modulation for comfortable wear during passive states and enhanced support during active use.

Emergency shelter applications requiring both structural rigidity for stability and compliant surfaces for safety.

This breakthrough in stimuli-responsive materials opens new avenues for adaptive soft machines across multiple domains:

Future work will focus on developing multi-stimuli responsive materials that can respond to various environmental triggers including temperature, pH, magnetic fields, and electrical signals for enhanced adaptability.

Integration with sensor networks and machine learning algorithms will enable autonomous stiffness modulation based on real-time environmental feedback and task requirements.

Development of biocompatible versions for medical implants and prosthetics that can adapt their stiffness to match biological tissues and respond to physiological conditions.

This research establishes a new paradigm for soft material design by successfully integrating structural stiffness regulation with compliant contact capabilities. The bio-inspired approach demonstrates that it is possible to achieve both high structural performance and soft interaction properties in a single material system. The 21.5× stiffness enhancement while maintaining contact compliance represents a significant advancement in programmable materials for adaptive soft machines. Future applications will span from advanced robotics to biomedical devices, enabling new levels of versatility and performance in soft mechanical systems.

@article{ma2024synergizing,

author = {Ma, Ke and Zhang, Jie and Sun, Ruotong and Chang, Binhan and Zhang, Siyuan and Wang, Xiaojun and Wu, Jianing and Zhang, Jinxiu},

title = {Synergizing Structural Stiffness Regulation with Compliance Contact Stiffness: Bioinspired Soft Stimuli-Responsive Materials Design for Soft Machines},

journal = {Advanced Engineering Materials},

volume = {26},

number = {18},

pages = {2400461},

year = {2024},

}